|

|

Offset Crankshaft

What is the Speed of a Piston

with an Offset Crankshaft?

The Question:

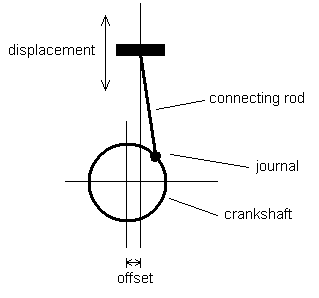

Some engines have an "offset" crankshaft.

An example of this can be seen in this article about the

Toyota RAV4's Engine.

So, I decided to see how an offset crankshaft changes the equations for

the speed of a piston.

Equations:

To derive an answer, I first

thought I would represent the rotation of the crank as a circle where the

center of the circle would be the axis of the crankshaft and the

circumference represents the rotation of the center of the journal. The

piston's connecting rod is then represented as a straight line. Since the

piston and the top of the piston rod travel the same vertical velocity,

the piston itself is not a factor. Since this article is about the offset

crankshaft, notice that the center of the circle representing the rotation

of the journal is offset from the vertical line which denotes the center of

the piston. Figure 1 shows this representation.

|

| Figure 1 |

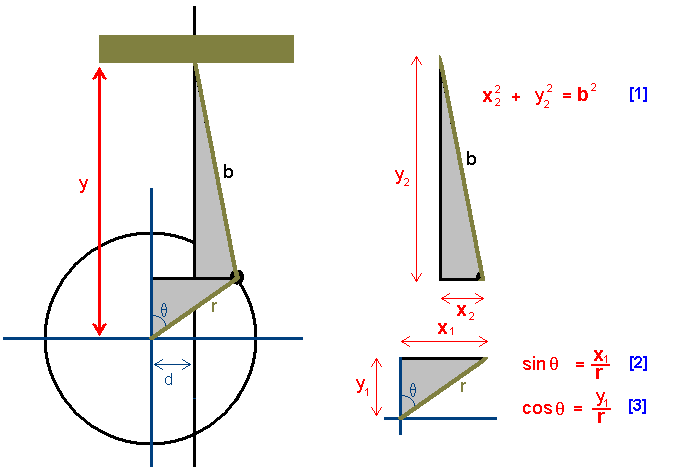

Next, I derived a displacement equation to relate the following:

- The length of the piston rod

- The radius of the crankshaft

- The angle of the radius relative to a vertical line through the axis

of the crankshaft

- The offset of the axis of the crankshaft from the vertical path of the piston

This relationship was much more complicated to derive than without the offset.

The solution came by viewing the system as two triangles and finding the relationships

between them.

The goal of this derivation will be to solve for y in terms of r, d,

b and θ. The first step is to list the basic relations that are easy to spot.

Here I show the relationships for sin, cos and the Pythagorean theorem.

|

| Figure 2 |

|

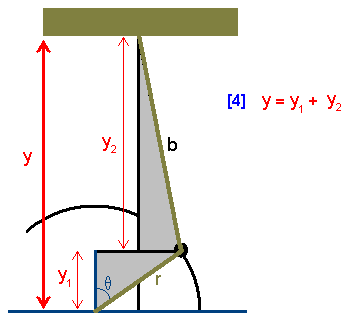

Since I want to solve for y, I go ahead and list

the relationship for y

in terms of the sum of the heights of the two triangles.

|

|

| Figure 3 |

|

|

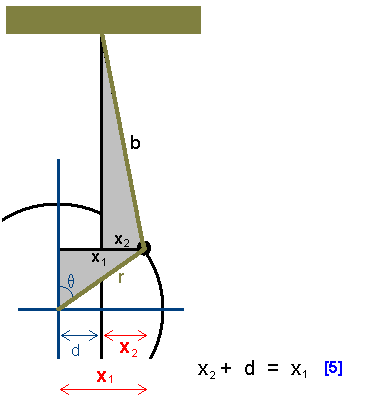

The last of the geometric relationships involves the x dimensions of the two

triangles and the offset.

|

|

| Figure 4 |

|

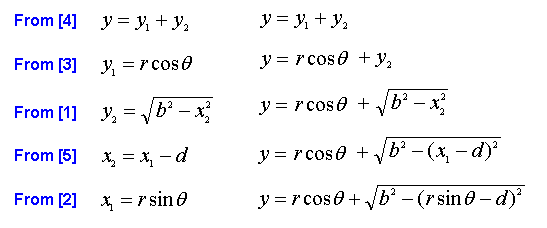

The following table summarizes the above relationships. A rewrite of the

equations is also performed in cases where solving for a specific term

will help in the goal of solving for y.

By performing substitutions of the above relationships, we can solve for

y in terms of r, d, b and θ.

On the left you will see the specific term from the above table, on the

right you will see how this term is used when substituted.

|

| Figure 5 |

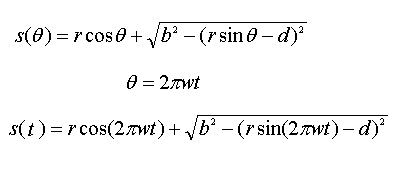

The displacement equation is then used as a function of time by substituting

a function of time for the angle. This relation of θ=2πωt is the

same as with the non-offset crankshaft. As before, I am still going on the assumption that

the rotational speed of the crank is constant when the engine is held at a constant RPM.

|

| Figure 6 |

The next step is to take the first and second derivative of the displacement

equation to obtain an equation for velocity and acceleration respectively.

The derivatives of the displacement equation were derived using a

wonderful program called maple.

The graphs and equations shown here are derived from images produced with

maple.

|

| Figure 7 |

Example:

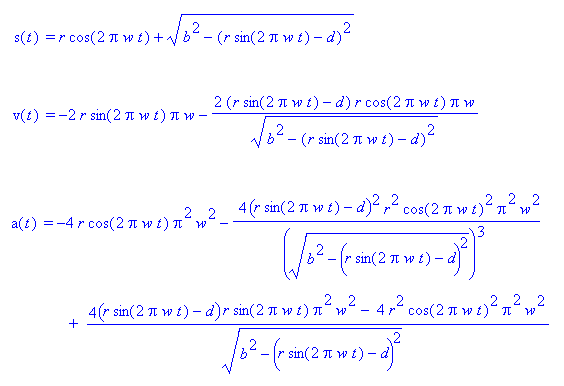

Now let's use some numbers for these equations and generate some graphs.

I will spare you the actual equations for this example because they are ugly.

I have not been able to actually measure the radius of a crankshaft nor

the length of a piston rod. So, I am going to use a fictitious example with

the following dimensions: radius of 3.5 inches, piston connecting rod length

of 5.5 inches, RPMs of 6000 revolutions per minute. The following graphs will

show the equations without an offset (d=0) in red, and the

equations with a 1 inch offset (d=1) will be shown in blue.

The time for these graphs is measured in minutes, furthermore, all times

should be assumed as minutes unless explicitly denoted as seconds.

An Excel spreadsheet

is also provided to allow for custom dimensions to be entered.

Displacement:

r=3.5 inches, b=5.5 inches, ω=6000

Blue: d=1 inch, Red: d=0 inches

|

| Graph 1 |

We can definitely see a difference in the displacement graphs for these two scenarios.

It also appears that the graph with the one inch offset has a longer stroke. We will

compute this stroke length after we determine the time at which the velocity is zero.

However, we can

easily tell that the top-dead-center (TDC) and bottom-dead-center (BDC) occur at

different times for these two cases. Also, note that at t=0, we are not quite at

TDC actually we are 6.4° from TDC.

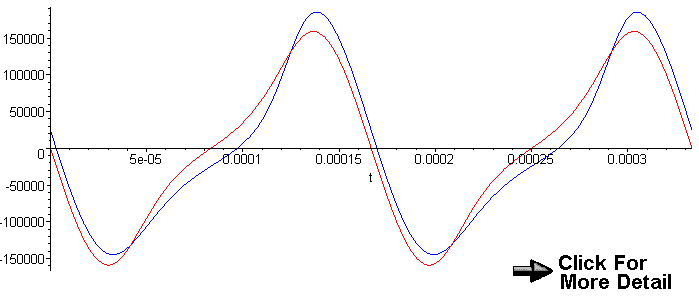

Velocity:

r=3.5 inches, b=5.5 inches, ω=6000

Blue: d=1 inch, Red: d=0 inches

|

| Graph 2 |

The two velocity graphs definitely show a major difference. We can also observe that the

velocities are different at TDC for and BDC for the two system.

With some work, I found that the velocity is zero at about

t=0.000002953412 and t=0.000097222225 minutes. We can also see that the piston

reaches a higher velocity on the up-stroke than on the down-stroke.

| With an offset of 1 inch |

| t (minutes) |

Angle(degrees) |

v(t) (inches/minute) |

s(t) (inches) |

| 0.000002953412 |

6.379 |

0.0019 |

8.94427191 |

| 0.000097222225 |

30.000 |

0.0058 |

1.73205081 |

|

Since the velocity is zero at both the top (TDC) and the bottom (BDC) of the stroke,

we can now find the length of the stroke. By taking the difference

in the two displacements for the time of TDC and BDC, we come up

with about 7.2 inches for the stroke: s(0.000002953412) - s(0.000097222225) = 7.21222110.

The example without the offset had a stroke length of 7.00 inches.

So, the stroke is indeed longer with the offset crankshaft in

this case.

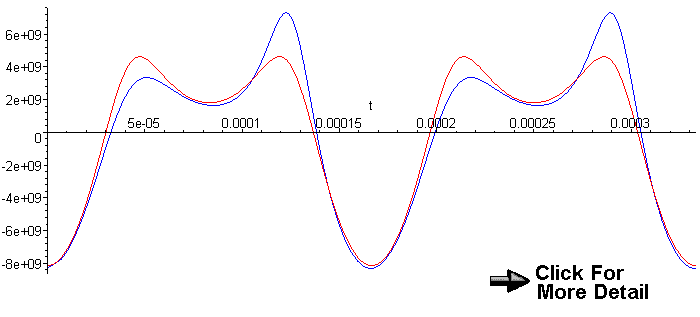

Acceleration:

r=3.5 inches, b=5.5 inches, ω=6000

Blue: d=1 inch, Red: d=0 inches

|

| Graph 3 |

Sorry, but I am not quite done with this page.

|

|